A Solution for Every Distiller

Tequila Distillers

The primary concerns for tequila distillers are the agave plant byproducts – agave bagasse and vinasse.

Agave Bagasse – The agave bagasse generates high levels of total suspended solids (TSS) as a result from the agave fibers that must be separated prior to discharge.

Vinasse – The vinasse increases the organic load (BOD and COD) in the wastewater due to its sugars, alcohols and other organic compounds. These must be reduced prior to discharge to avoid surcharges and out-of-compliance fines.

Whiskey/Whisky and Bourbon Distillers

Whiskey distillation produces two unique waste streams that must be considered – the pot ale and the spent lees.

Pot Ale – The pot ale produces a high-volume waste stream with high levels of organics (BOD and COD) and total suspended solids (TSS) that vary from batch to batch and therefore require specialized treatment that can handle those variations.

Spent Lees – The spent lees produces a lower-volume waste stream containing oily fats and copper, both of which must be treated to avoid fines from the utility.

Rum Distillers

The sugarcane utilized for rum distillation produces two byproducts that affect wastewater treatment.

Sugarcane Bagasse – The sugarcane bagasse is your primary waste product and must be separated from the waste stream prior to treatment to avoid elevated levels of total suspended solids (TSS).

Cane Juice – The cane juice contains high organic loads (BOD and COD) which must be treated prior to discharge to avoid out of compliance fines and sewer surcharges.

Vodka & Gin Distillers

Vodka and gin are both produced from starchy starting materials which results in wastewater with both a high starch content and high solids content.

Starchy Wastewater – Starchy wastewater is high in COD and viscosity, making it one of the most difficult to treat wastewater compositions. Therefore, it’s important to separate the high-starch waste streams generated during the mash phase for specialized treatment prior to combining with the full flow.

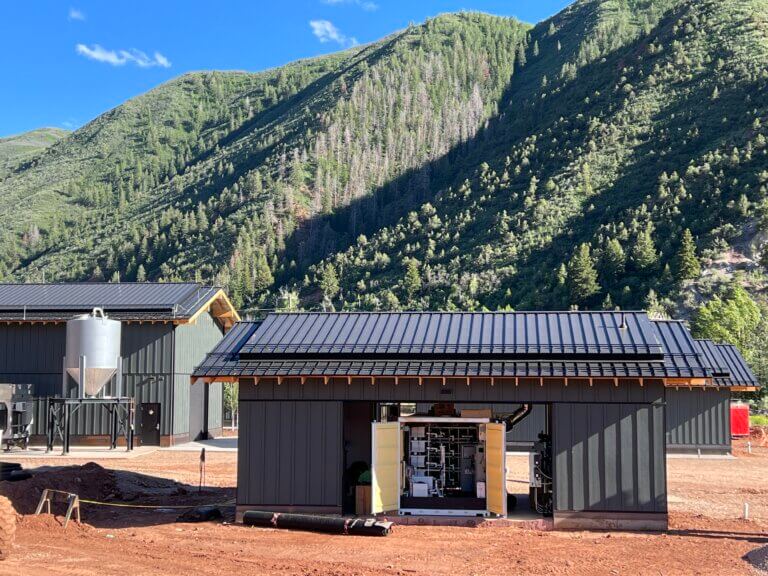

Your All-Encompassing System

Solving Every Distillery Wastewater Challenge

BETT (BioElectrochemical Treatment Technology) changes the game for distillery wastewater treatment. With BETT you’ll:

- Efficiently treat high organic loads (BOD and COD) and total suspended solids (TSS) onsite.

- Ensure regulatory compliance under dynamic operating conditions.

- Lower operational costs and increase efficiency to improve your bottom line.

- Enable circularity and water reuse at your facility.

- Reduce operational risks and support business growth.

20-60%

Cost Savings

Say goodbye to hauling fees, high operational bills and unexpected sewer surcharges with our revolutionary BETT solution.

100%

Performance Guarantee

Never worry about compliance again. We guarantee permit compliance so you can discharge direct from our system.

60-95%

BOD Removal

Handle BOD concentrations higher than conventional technologies with up to 95% removal for discharge quality standards.