Originally published in Smart Water Magazine

Challenges and Applications of MFC in wastewater treatment

While early attempts to commercialize microbial fuel cells (MFC) were not successful, recent developments have broadened application and provide an opportunity to improve wastewater treatment. They do not provide a silver bullet, but MFCs do provide a sustainable way of treating wastewater that conventional treatment has not been able to treat effectively.

Basics of MFC system

A microbial fuel cell uses bacteria to transform chemical energy into electricity. The fuel source can be any form of biodegradable organic matter, such as sugar or wastewater. Since the bacteria are simultaneously consuming organic material and cleaning the water, MFC is ideal for wastewater treatment.

The microbes in the system are naturally occurring bacteria which perform extracellular electron transfer, releasing electrons as part of the respiration process. These electrons are captured at the anode and transferred to the cathode to generate electricity, constantly pulling energy away from the bacteria and accelerating the bacterial metabolism. By controlling the rate at which electrons are removed, the system controls treatment rate, speeding up the treatment process relative to conventional systems.

Challenges and limitations of MFC

Interest in the technology peaked in the 2000’s, but as researchers realized the inherent limitations of power generation, the focus shifted from electricity production to wastewater treatment. For MFC to be a viable option for wastewater treatment, they need to be scaled up to accommodate large volumes of incoming wastewater, which has proven challenging for several reasons.

As electrochemical devices, they require certain aspects to be met like minimal distance between the anode and the cathode to minimize electrical losses. Unfortunately, minimal distance or narrow MFCs are prone to clogging. Bigger electrodes mean the electrons must travel further, which imposes ohmic losses, reduces electricity generated and lowers treatment efficiency. To optimize MFC for wastewater treatment, they must be relatively small.

Another challenge is becoming cost-competitive with other wastewater treatment technologies. The materials used are expensive, including membranes to separate the electrodes and a catalyst (typically rare metals such as gold or platinum) to produce enough power. Membranes separating the anode and cathode are prone to fouling, adding cost and maintenance.

New Approaches

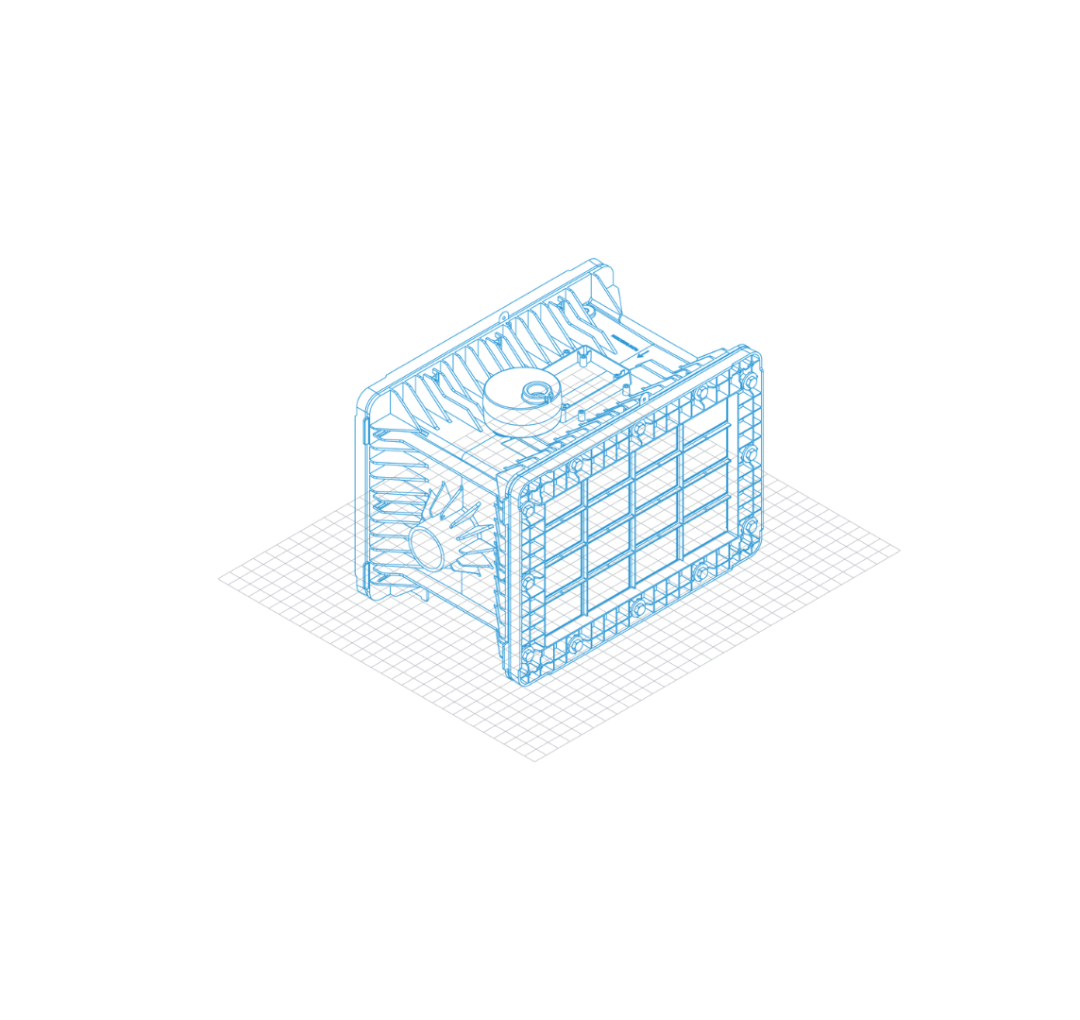

Aquacycl developed the first-commercially viable microbial fuel cell for wastewater treatment by addressing the design limitations above. The system was optimized for wastewater treatment efficiency instead of energy recovery. Rather than scaling the system within a single unit, Aquacycl created a modular approach, where each microbial fuel cell reactor is about the size of a standard car battery, and they are stacked together to increase treatment quality and volume capacity. The small size means they don’t face the mass transfer losses inherent in larger system designs, and it doesn’t use a membrane, which eliminates biofouling and makes the system more cost-effective and efficient.

Since it’s impossible for one reactor to remove all the organics from the wastewater, the reactors are connected in hydraulic series or treatment train. As the wastewater flows through the treatment train, it gets increasingly cleaner until it reaches the desired water quality. To increase the volume of wastewater treated, the system has multiple treatment trains operating in parallel. The added benefit of this is easy serviceability and maintenance, allowing the system to be operational while a single treatment train is being maintained.

The electricity production from the MFC enables real-time remote monitoring, troubleshooting and control and earliest detection of any problems in the system.

Applications and future of MFC

Microbial fuel cells will likely never replace a centralized treatment facility treating millions of gallons of wastewater per day. The best applications today are industrial pre-treatment of challenging to treat, low-volume wastewater. This could be high-organic concentration streams from food and beverage manufacturing, or toxic compounds from hydrocarbon processing. Today, these streams are managed in an unsustainable way, by trucking, incineration or land-application. They are a natural fit for MFCs as they are costly to manage and are not able to be treated by conventional technology.

As costs of the technology come down further, future applications include manure management and distributed sanitation for rural communities or disaster areas. By overcoming some of the key challenges to scaling, MFCs can be a viable alternative for some waste streams. As we mentioned earlier, they are not a silver bullet, and likely will only address a small portion of the total wastewater treatment market, but the small, modular nature and energy-neutral operation offers more flexibility and potential for treatment without a sewer or electricity grid.

Looking at the Gartner hype cycle, we can see that MFC are emerging from the trough of disillusionment, where early hype turned into skepticism and now, we are starting to see early adopters implementing the technology. As we continue to see success, companies can find the right application for MFCs.