Sugar processing is a critical part of the food supply chain, and the environmental impact of processing and refining has been historically high in terms of water intensity and wastewater pollution. The industry has successfully reduced water usage through efficiency and reuse strategies. However, the resulting wastewater is highly concentrated in organics and increasingly costly to manage as the high-strength streams cannot be directly treated in existing on-site facilities or discharged to sewer without significant surcharges or permit restrictions. Municipal surcharges and trucking costs for wastewater management erode margins. Recent advances in microbial fuel cell technology can bring significant reductions in wastewater management costs by acting as a pretreatment step making all downstream treatment more efficient, reducing maintenance, energy consumption and required chemicals. With reference to case studies, Aquacycl’s patented BioElectrochemical Treatment Technology (BETT®) has been shown to be cost-effective in reducing wastewater management costs by 20-60% relative to current practices.

Keywords: wastewater treatment, BioElectrochemical Treatment Technology, Aquacycl

Sugar processing’s wastewater challenge

Sugar processing is one of the most-water intensive industries and the corresponding wastewater can have a major environmental impact if not carefully managed. Large quantities of effluent and high organic concentrations are environmental problems, polluting water and land, and changing the chemical and physio-chemical properties of rivers and soil. Odor from lagoons near residential communities is a major problem, often resulting in fines, lawsuits, and complaints from the community.

The wastewater from sugar refining and processing contains high brix (which translates to high Chemical Oxygen Demand or COD), total suspended and dissolved solids (TSS and TDS), color, low pH and odour. The composition of the effluent makes it difficult to treat or discharge. Without proper treatment and/or dilution, the high COD will induce depletion of oxygen in receiving water bodies, negatively impacting aquatic life. Land application of the wastewater could lead to soil deterioration and severely inhibit seed germination if not amended with other constituents.

Wastewater treatment in sugar refining and processing

Sugar refining and processing wastewater is usually treated with a combination of physico-chemical and biological methods. The main components of sugar industry wastewater are sugars and volatile fatty acids, which are biodegradable, implying the use of aerobic and anaerobic treatment processes, or the wastewater is trucked offsite for land application when no treatment solutions are available. Trucking is often the only option and can cost upwards of one million dollars (US) per year, per facility. The selection of wastewater treatment depends on economics, as well as proximity to local community, regulatory permits, and land availability. High brix concentrations make it impossible to discharge wastewater directly to sewer without pretreatment as it can create toxicity shocks to the local utility. COD concentration can be 80,000 mg/L or higher, roughly corresponding to 8 brix (when considering sucrose as the primary sugar), which requires dilution and nutrient amendments for both anaerobic and aerobic treatment.

Anaerobic lagoons are the most cost-effective and can be used to produce biogas to reduce energy costs. These are the most common onsite treatment for beet sugar processing, which is often located in rural areas. However, they require large land areas and generate hydrogen sulfide, which creates odours that disrupt local communities. Urban sugar refiners do not have this option due to limited land area and proximity to local communities, meaning the only option is to truck the high-strength wastewater.

Aerobic treatment requires high energy consumption and is usually not feasible unless combined with anaerobic treatment. For example, one North American company requires over 600 horsepower (447 kW) to treat a 20,000 gallon (91,000 litres) per day aerobic pond and requires daily sludge management.

Pretreatment to reduce costs

Microbial fuel cells have long been explored as a waste-to-energy approach that provide energy-neutral or energy-positive wastewater treatment. However, until now, attempts to commercialize the technology have failed due to high material and production costs, scalability challenges, and efficiency losses that minimize energy recovery during the treatment process. Aquacycl® is the first company to solve the technical challenges that have previously limited the commercial use of microbial fuel cell technology. This innovative treatment technology is now ready for deployment, creating immediate value for industrial customers.

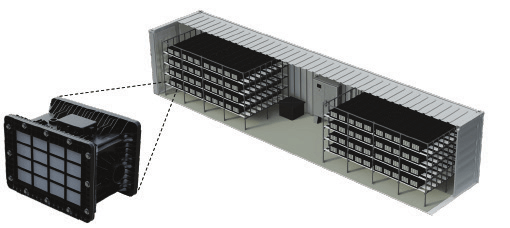

The BioElectrochemical Treatment Technology (BETT®) is the only cost-effective, small footprint solution, for directly treating organic wastewater with chemical oxygen demand (COD) values up to 300,000 mg-COD/L, total suspended solids (TSS) up to 30,000 mg- TSS/L and a wide range of temperature profiles (10ºC – 50ºC). BETT reactors are placed in a series of treatment trains housed in shipping containers, creating a modular and flexible approach to wastewater management (Fig. 1).

In BETT reactors the organic compounds present in wastewater are bioelectrochemically transformed into dissolved carbon dioxide (bicarbonate), new water and electricity as DC current.

These BioElectrochemical systems are significantly more energy efficient than any other technology on the market because of low-pressure and low flow rate operations that reduce horsepower requirements. BETT enables water reuse when combined with complementary post-treatment technologies. BETT is also remotely monitored and controlled, which minimizes onsite operator time.

Aquacycl has been working with sugar refiners, confection, and beverage companies to identify opportunities for reducing wastewater management costs by 20-60% relative to current practices. BETT can be applied as pretreatment for:

- Direct discharge to utilities, eliminating trucking and surcharges.

- Minimizing anaerobic lagoon size and odour.

- Optimizing aerobic treatment by reducing energy consumption and concentration shocks

Pretreatment to direct discharge, eliminating trucking and surcharges

Anaerobic lagoons require large amounts of land. For refiners that are located in urban areas where it is not feasible or economical to install onsite treatment, the only option is to truck as the wastewater is often too concentrated to discharge to the utility. BETT systems can be used as small footprint pretreatment to reduce COD, TSS, color and nitrogen, enabling direct discharge to sewer with minimal surcharges and guaranteed permit compliance. Combined with complementary technologies, BETT can enable water reuse on site.

Minimizing anaerobic lagoon size and odour

BETT systems are anaerobic technologies that use naturally existing electrically active bacteria to accelerate the hydrolysis of complex carbon sources and enhance fermentation rates to generate the smaller volatile fatty acids that methanogens prefer. As a pretreatment step, the BETT systems normalize the feedstock, reducing adverse impacts of production variability, pH, and temperature. By reducing the complexity and variability of the carbon chains and other parameters, capped anaerobic lagoons and high-rate anaerobic digesters operate more consistently, with less operational input, improved treatment times, fewer toxicity events and higher methane production.

Pretreatment to on site aerobic wastewater treatment plants

Aquacycl technology is an ideal pre-treatment step to onsite or utility- operated aerobic wastewater facilities for sugar industry wastewater. BETT systems can reduce the organic loading entering the activated sludge-based treatment. The lower organic concentrations will significantly reduce plant size, energy cost, biomass production, and prevent overloading of the treatment plant.

The BioElectrochemical approach offers many benefits including low-cost operation due to remote monitoring and control abilities, electricity offsets and energy efficient operations, low chemical addition and/or no nutrients dosing, small footprint, negligible sludge, no environmental impact and reliability due to fixed-biofilms in the system.

Case studies using BioElectrochemical Treatment Technology

Confectionery producer

A confectionery company faced challenges with a specific waste stream from process wastewater with an extremely high sugar content. This specific waste stream (“sugarwater”) requires pretreatment or dilution prior to land-application; and cannot discharge to the onsite aerobic treatment facility due to carbon toxicity issues that would occur.

Aquacycl installed a fully automated and containerized 12-reactor demonstration unit (BETT Demo Unit) to continuously treat 160 gpd (727 litres/day) of the sugarwater and enable a clear understanding and cost model for how BETT systems could be applied at full-scale for sugar industry wastewater treatment. System COD removal and power production were monitored during the demonstration. The inflow sugarwater COD ranged from 100,000-300,000 mg/L under continuous flow conditions. Batch operations were also required corresponding to production shutdowns associated with holidays and other facility operations.

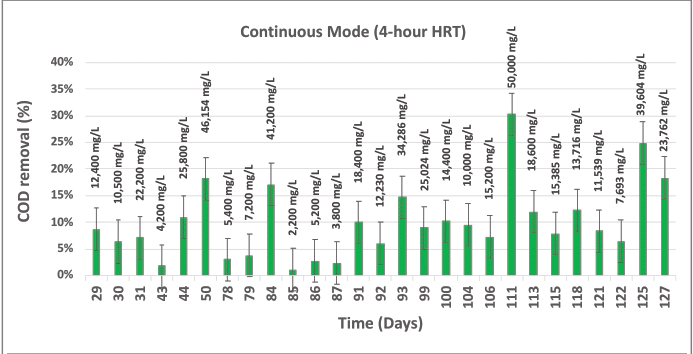

BETT Demo Unit demonstrated its applicability and efficiency in treating high-strength sugar containing wastewater. The BETT Demo Unit accomplished an average 10% COD removal (18,377 mg/L) in a 4-hour hydraulic residence time with only 12 BETT reactors in hydraulic series (Fig. 2). The COD removal capacity of the system ranged from 2,200 mg/L to 50,000 mg/L. Lower removal rates were observed when reestablishing continuous mode after planned facility shutdowns. The system only requires 24-48 hour recovery period to reach normal performance metrics after a system shut-down or batch operation. These results showcase how microbial fuel cells can be used for treatment of high-organic wastewaters. Further, the system scales modularly. By adding more reactors in a treatment train, and operating multiple treatment trains, the BETT reactors can be used to remove up to 95% of organics with flows between 2,500 gpd to 10,000 gpd.

| Table 1: Results from BETT demonstration unit with 12 reactors | |

| COD concentration | Between 100,000 and 300,000 mg/L |

| BETT Demo Unit COD removal rate | 10% |

| Biomass production | 0.03 to 2.5% from COD removed |

| BETT Demo Unit Net Energy Recovery | 22 kWh/day (enough power to offset 50% of the total energy demand of demo) |

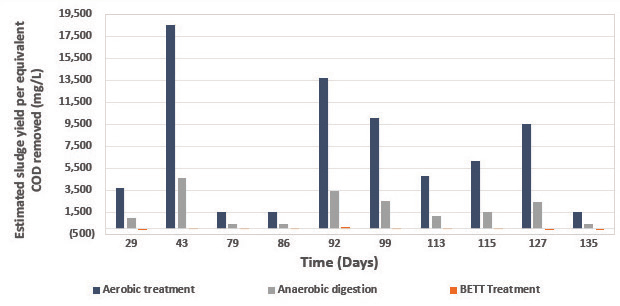

One benefit of Aquacycl BETT system is the limited biomass production. During sugarwater treatment the BETT Demo Unit only generated 0.03 to 2.5% biomass from the COD removed (Table 1). In comparison to other conventional technologies, this translates to negligible biomass production (Fig. 3). The biomass generated from BETT ranged between 4 to 112 mg/L VSS compared to 381 to 4,615 mg/L VSS if the wastewater was anaerobically treated; and 1,522 to 18,462 mg/L VSS for aerobic processes (assuming identical COD loading in all cases).

The Net Energy Recovery (NER) from BETT was up to 1.6 kWh/ kg-COD removed comparable to anaerobic digestors combined with methane conversion to electricity. The electricity was generated as direct DC power, with no intermediate methane production.

Soft drink producer

Soft drink manufacturing process also generates wastewater with very high sugar content. Aquacycl evaluated BETT reactor treatment rates for soft drinks wastewater with COD concentration in the range of 65,000 – 150,000 mg/L. The average BETT reactor removal rate was 2,900 mg/L per reactor per day, which was double the removal rates demonstrated with sugarwater. The implementation of BETT system for soft drinks manufacturers can result in 10%-30% cost savings for wastewater management, per facility.

Sugar refinery

A sugar refiner faced a challenge with their wastewater when the increased production had resulted in 100-150% increase in effluent volume far exiting their wastewater permit compliance. The latter led to production limitations and trucking of 50% of the wastewater. To meet wastewater permit requirements and eliminate trucking, organic carbon had to be reduced by 87.5% in order to send all wastewater to municipal treatment. After preliminary laboratory and cost analysis, it was established that the refinery could save 50% relative to current practices by applying BETT for reducing carbon, nitrogen, color and TSS.

Conclusion

As water and wastewater management becomes increasingly important to the sugar industry, companies can use new technologies to decrease wastewater management costs and reduce their environmental impact.

Recent advances in microbial fuel cell technology enable treatment of high-brix (high COD) wastewater, which until now required dilution and/or hauling. By reducing COD, TSS, nitrogen and color, BioElectrochemical Treatment enables direct discharge, permit compliance, and more efficient downstream treatment for sugar industry wastewater.

Sofia Babanova

Aquacycl, 6342 Ferris Square, San Diego CA 92121, USA Tel: +1.505.358.8044 sbabanova@aquacycl.com