Solving PepsiCo’s Biggest Process Water Challenges

Reduce BOD in Process Water

Are you faced with unpredictable and costly monthly sewage bills? The culprit is BOD, and manufacturing facilities produce some of the highest BOD process water.

Bad batches, starchy process water, and expired products all increase BOD in the process water you discharge, and lead to unpredictable monthly bills.

Handle production variability with ease. Aquacycl’s process water treatment ensures you maintain compliance to avoid costly fines, reduce business risks, gain predictable pricing, and enhance operational efficiency.

Achieve Sustainability Goals

Utilize process water to achieve your pep+ carbon and water goals without forgoing your operations or damaging your bottom line.

Reduce Scope 1, 2 and 3 emissions through Aquacycl’s energy-neutral, methane-free process water treatment that helps you decarbonize your value chain.

Enable process water reuse to achieve a 1.2 water-use-ratio in beverage facilities or 0.4 water-use-ratio in convenient food facilities in water stressed areas.

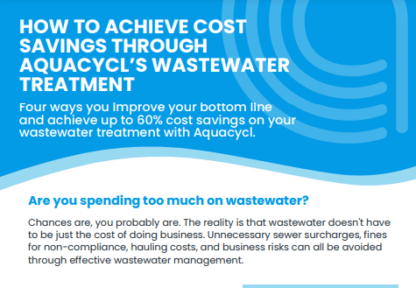

20-60%

Cost Savings

Say goodbye to hauling fees, high energy bills and unexpected sewer surcharges with our revolutionary BETT solution.

100%

Compliance Guarantee

Never worry about compliance again. We guarantee permit compliance so you can discharge direct from our system.

90%

Lower GHG Emissions

Than alternative technologies. Minimize Scope 1, 2 and 3 emissions from wastewater treatment.

With Aquacycl’s Process Water Treatment You Will:

Reduce Scope 1, 2 and 3 emissions

Achieve your pep+ climate goals through GHG emission reductions across Scopes 1, 2 and 3, while eliminating methane emissions entirely from treatment.

Reduce your water-use ratio

Achieve your pep+ water goals by enabling onsite process water reuse to reach your target water-use ratios even in water-stressed facilities.

Slash operational costs

Cut those unnecessary hauling and sewage costs through onsite beverage and convenient foods process water treatment, slashing 20-60% of your operational costs from treatment.

Ensure reliable system performance

Effectively handle production variability with a process water treatment system that accommodates changes in flow, pollutants, product lines, and cleaning events.

Mitigate risk

Maintain permit compliance, stay ahead of regulation changes, and eliminate production and business risks from your process water.

Improve energy efficiency

Lower your energy expenditure (and those high energy bills) with energy-neutral process water treatment.

PepsiCo Project Development

Check out our current projects in development

Aquacycl is working with several PepsiCo facilities to help them:

- Reduce BOD and TSS concentration from crusher, bad batches, and first rinse from batch room CIP

- Reduce energy consumption, sludge generation, and GHG emissions

- Reduce operational costs

- Achieve pep+ carbon and water goals

Pepsi Beverages North America

Former Vice President Engineering

“I would certainly recommend Aquacycl, my experience with them has been very positive”

PepsiCo

Manufacturing Leader

“One other cool thing about them being electrogenic — you can hook up probes to their computer and they can actually, from down in San Diego, remotely monitor each cell and tell you how healthy the bug colonies are in each cell because they’re releasing these electrons as they eat sugar,”

Fast Company

Read More

“On average, the system at the Pepsi plant is eliminating 110 tons of greenhouse gas emissions per month. It also saves the company money because its bills from the utility have dropped.”