Wastewater treatment is a major challenge when it comes to population growth and expanding production in various economic sectors.

Wastewater is a byproduct of virtually every human activity and can contain a variety of pollutants, each of which differs in their effects on the environment and the processes required to treat them.

Globally, only about 20% of all wastewater gets treated, with the rest being discharged with minimal to no treatment. And, just to treat this portion of wastewater, we are releasing greenhouse gas (GHG) emissions greater than the entire shipping industry. As industries and cities increasingly strive to achieve their net-zero goals, they need to consider the impact of wastewater on these.

Consequences of untreated wastewater include ecological damage, polluting drinking water, and increased greenhouse gas emissions, with the effects varying depending on the source of wastewater.

The three major categories of wastewater are as follows:

1. Municipal wastewater

2. Industrial wastewater

3. Agricultural wastewater

Each category of wastewater poses its own distinct challenges with regards to treatment needs and the technologies used to address them, particularly regarding secondary wastewater treatment, which deals with organic pollutants in the wastewater.

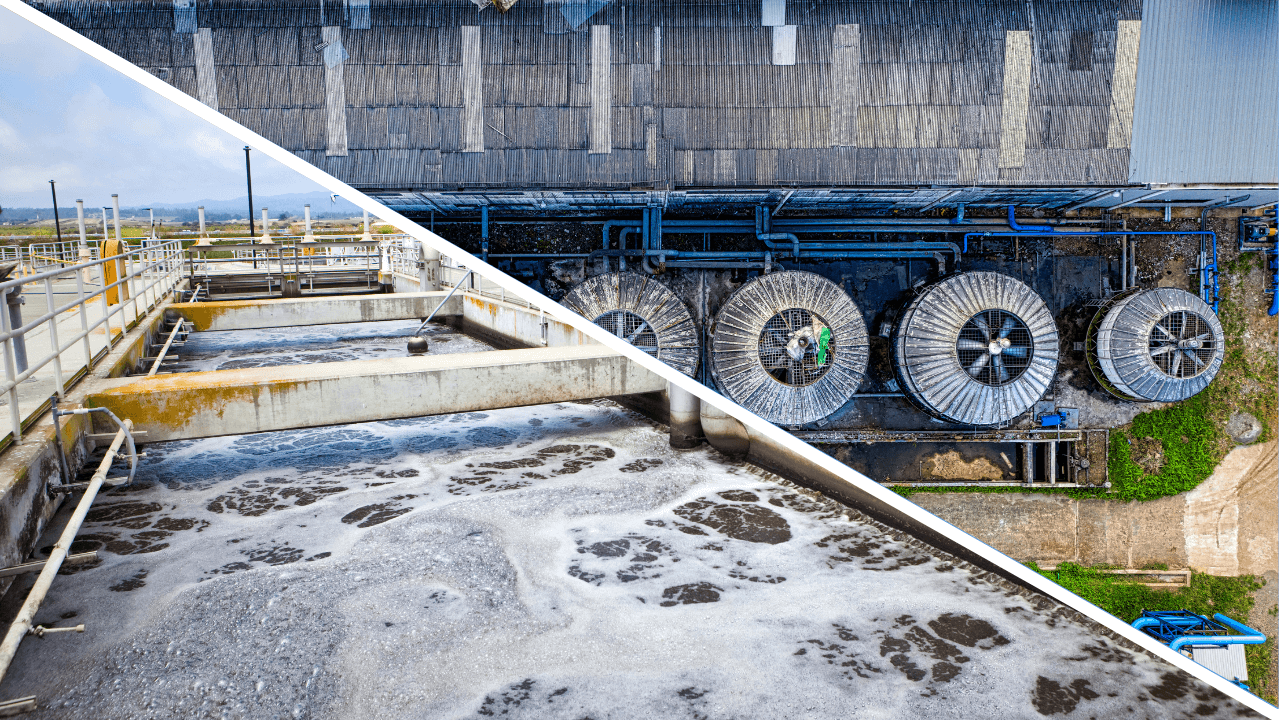

In this article, we explore municipal and industrial wastewater treatment, including some of the complexities of treating each and common technologies used for each form of wastewater.

Municipal Wastewater and Relevant Technologies

Municipal wastewater, commonly referred to as sewage, is the effluent that comes from domestic households and businesses.

Municipal wastewater tends to be more diluted compared to industrial wastewater, and typically contains fewer toxic compounds, although this is not always the case.

Municipal wastewater treatment challenges

Municipal wastewater has a few specific challenges when it comes to consistent and effective treatment.

The following are a few examples:

1. Stormwater fluctuations

Because municipal wastewater usually includes storm drain effluent, fluctuations in weather lead to increases or decreases in the total volume of water produced. During periods of higher volumes, stormwater can overwhelm treatment facilities, causing direct discharge of sewage and stormwater to the environment.

Additionally, this leads to variations in the strength of wastewater and the contaminants it contains, which can make it difficult to keep treated wastewater within acceptable contaminant levels during storm season.

2. Aging infrastructure

Like many areas of human development, populations tend to grow faster than the infrastructure that supports them, and this includes municipal wastewater treatment plants. Larger populations proportionally increase the demand on municipal treatment facilities, which means they must scale up or upgrade to ensure they can meet rising demands.

Across all wastewater treatment plants in the US, they are operating at 81% of design capacity, and 15% are at or have exceeded capacity. Investment in infrastructure has lagged what is required, and according to the American Society of Civil Engineers, there is a $105 billion funding gap for drinking water and wastewater infrastructure projected over the next two decades.

3. Freshwater usage reduction efforts

With the overall push to reduce freshwater usage in areas of high water-stress, wastewater streams have become more concentrated in these localities. Higher concentrations require more intensive treatment, increasing the need for capital expenditure to upgrade municipal plants.

Overall, the challenge boils down to an increased need for investment in municipal wastewater treatment plants, including size upgrades and installing improved technology.

Municipal wastewater treatment technology

Most municipal wastewater treatment depends on aerobic processes to deal with organic compounds within the wastewater stream. The following are a few common technologies used in municipal wastewater treatment.

Activated Sludge

Activated sludge is a biomass layer contained in a treatment tank and consists of microorganisms that digest organic materials in the water and rely on aeration to maintain the correct microorganism blend.

Activated sludge is effective at treating low to medium strength organic wastewater such as municipal effluent but has a high energy demand due to the aeration requirements.

Trickling Filters

Trickling filters involve bacteria attached to a medium through which wastewater is filtered through. It is a simple biological process that can rapidly reduce biological oxygen demand (BOD) pollutants and can handle reasonably high concentrations.

However, it requires maintenance to ensure the bacterial colonies remain aerobic and that excess slime is removed as it builds up.

Membrane Bioreactors (MBR)

Membrane bioreactors combine activated sludge with a membrane filtration unit. They are very efficient and have advantages over conventional activated sludge methods. They generally have a smaller footprint and produce high quality effluent free from bacteria and pathogens, reducing tertiary disinfection needs.

Often, MBR treated effluent can be discharged directly and to receiving bodies of water or reclaimed for irrigation and other non-human consumption uses.

Industrial Wastewater Challenges and Technologies

Industrial, or point source, wastewater consists of the effluent from various manufacturing and production facilities. It is typically much stronger than municipal wastewater and contains higher levels of toxic contaminants and organic compounds. Industrial facilities will have a discharge permit, which provides the levels of pollutants they are allowed to discharge. Compliance and enforcement of these depends on the company’s priority and the city’s resources to monitor.

Industrial wastewater treatment challenges

Onsite treatment of process wastewater typically falls outside the expertise of the company and distracts from their core business operations. The specialized knowledge, cost and technology to effectively treat wastewater usually means that companies will not invest in onsite treatment until they are forced to by their local authorities.

Depending on the strength of the industrial wastewater and allowed permit levels, secondary treatment with anaerobic digesters may be required either in conjunction with aerobic treatment or in lieu of it. If discharging to a waterbody (rather than sewer), the requirements for treatment will be higher.

Common industrial wastewater treatment technologies

While there is some overlap between municipal and industrial technologies, industrial wastewater treatment often utilizes more specialized equipment to handle the concentrations of pollutants in the wastewater stream.

MBRs

Membrane bioreactors are also used for industrial wastewater treatment and rely on the same aerobic organisms used in municipal wastewater treatment. Depending on the strength of the wastewater, MBR’s can be a great way to handle secondary industrial wastewater treatment.

Anaerobic Digestors

Anaerobic digesters rely on bacteria and microorganisms in the absence of oxygen to metabolize organic pollutants. They have the advantage of lower energy costs and produce methane as a byproduct, which can be burned for energy production.

However, anaerobic digestion is more capital and personnel intensive than aerobic digestion but can save money in the long run. Depending on the strength of the wastewater, anaerobic digestion may be required especially when BOD levels exceed 10,000 to 15,000 ppm.

New & Emerging Technologies

Various new technologies aimed at addressing wastewater treatment challenges are hitting the market. One example of this is Aquacycl’s BioElectrochemical Treatment Technology (BETT).

This system provides point source treatment for industrial companies which can handle highly concentrated and challenging wastewater such as hydrocarbons, syrups, discarded product, or the first few equipment washdown from food and beverage manufacturing.

The containerized BETT system treats these complex organic streams using naturally-existing bacteria that generate direct electricity as they consume the organics. The electricity can be used to control treatment rate and remotely monitor the system. By removing the high concentrations of organics onsite, in a very low energy way, they have demonstrated 90%+ reduction in greenhouse gas emissions relative to conventional aerobic treatment.

BETT is effectively a new category of wastewater treatment that can be used in conjunction with, or as an alternative to traditional secondary wastewater treatment. BETT reduces the need to wastewater dilution or offsite transportation, helps facilities meet municipal discharge requirements, normalizes feedstock for anaerobic digestion, and can allow onsite re-use of the treated wastewater for irrigation and exterior cleaning.

The Bottom Line

Effective solutions for treating municipal and industrial wastewater are vital for protecting the environment, ensuring water security, and reducing global greenhouse gas emissions. While each wastewater stream poses its distinct challenges, both require a financial investment into upgrading treatment facilities and investing in new and improved technological solutions.

If you operate a facility that produces high-BOD wastewater, contact Aquacycl to learn how BETT can help you save money on wastewater treatment and reach your sustainability goals.